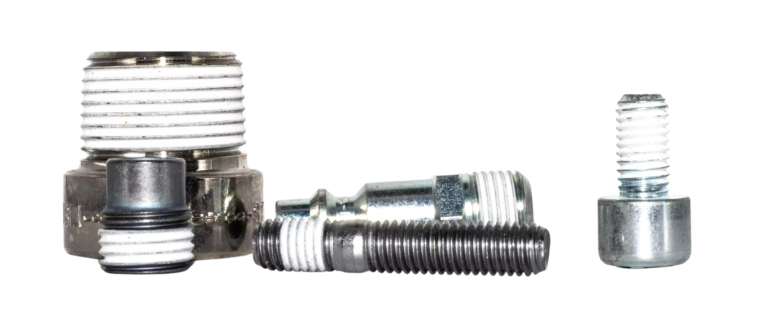

Sealing assembly parts

The sealing function is often complex and costly to achieve on mechanical assemblies.

Pre-coating fasteners provides a 100% reliable seal, easy to use and without assembly costs.

The product we deposit on your parts is dry, non-sticky and perfectly localized.

When assembled by screwing, press-fitting or crimping, the resin fills the gaps in the assembly, ensuring an immediate seal.

Many fluids can be sealed using the pre-coating technique:

- Compressed air and gas

- Oils and hydrocarbons

- Cooling and brake fluids

- Sprayed or immersed water

Benefits of sealing fasteners

- Eliminates assembly costs

- Replaces O-rings and flat gaskets, as well as pastes and liquid resins that are difficult to remove

- Perfect efficiency: 100% sealing with no “background noise” leakage

- Flawless quality: the presence of the sealing system is guaranteed and visible

- Immediate sealing after assembly, up to 50 bar on some assemblies

- High pressure ratings

- Tightness level up to IP67

- Control of technical parameters

- Good resistance to chemicals

- Works on all types of metal, but also on plastic parts

Our different techniques for sealing

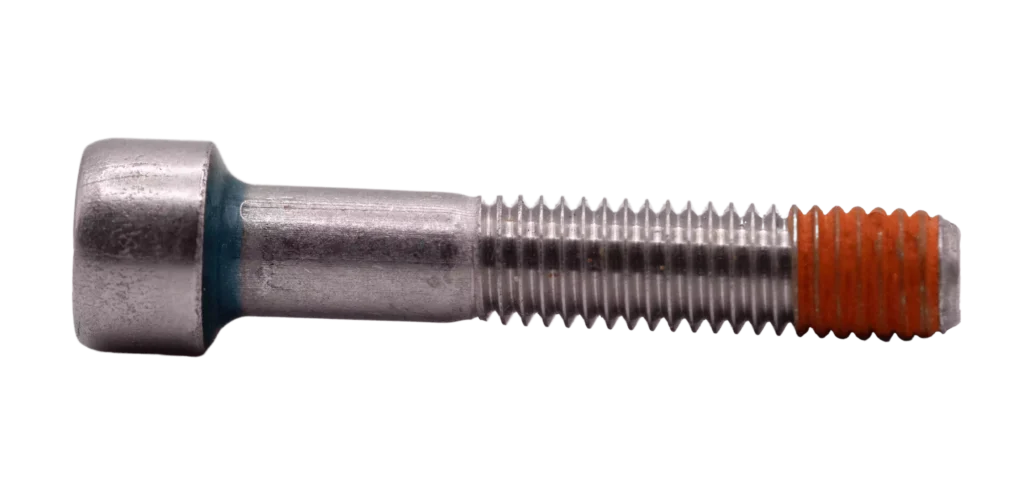

Under-head sealing of screws and crimped parts

Pre-coating consists of depositing a bead of product under the screw head to ensure an immediate seal after assembly.

Its reuse depends on the shape and profile of the interfaces.

Sealing of crimped parts

- Blind rivet nuts

- Crimp studs

- Small head rivet nuts

Sealing of screwed parts

- M2 to M4 electronics screws

- Screws for plastic

- Standard screws

- Threaded plugs

Performances

- Tension is maintained in screwed assemblies as the metal-to-metal contact is maintained.

- Compact sealing function design

- No added parts (washers, paste, etc.)

- Streamlined industrial process: automatic assembly using a vibrating bowl, etc.

- A lower overall cost than traditional solutions

Sealing of threaded parts

Pre-coated parts can be used in many fields: electronics, automotive, motorcycles, household appliances, electric motors…

Applications

- Screws, axis, studs

- Stoppers and connectors for fluids

- Sensor and contactor plugs

- Special parts

Performances

- Tension maintained in screwed assemblies thanks to preserved metal-to-metal contact

- Minimum space required for sealing function

- No additional components (gaskets, paste, etc.)

- Easier industrialization: automatic assembly by vibratory bowl

- Lower overall cost than conventional solutions

Sealing of tubes and socketed parts

Soprima has developed special expertise in the pre-coating of socketed parts.

Our pre-coating technique for tubes, axis and other smooth parts offers superior technical performance and substantial savings in a variety of sectors

Applications

Pump outlet cannula and rigid pipes

Press-fitted socketed smooth nozzles

Grit removal plugs

This type of sealing is primarily used in the automotive sector to seal many engine components.

Performances :

- Robust sealing for automobile fluid circuits

- 0 ppm application quality on large series

- Replaces Banjo-type threaded connectors

- Effective on aluminium, steel or stainless steel bar-turned tubing or seamless drawn tubing

- Replaces in-line bonded grit removal caps

Sealing combined with locking function

Fasteners to be sealed can also be secured to prevent loosening by adding a locking product to the threading: a micro-encapsulated adhesive such as threadlock or polyamide resin for repositionable parts.

Under some conditions (fluid, pressure, assembly design), locking products can also provide the sealing function on the threading.

Features and products

We have a wide range of products to meet a wide range of sealing requirements.

| Brand | Product | Color | Max use Temp. | On threaded parts | On smooth parts | Under head of threaded parts | Under head of crimped parts | ||

| Flat head | Counter-sund head | Standard head | Thin head | ||||||

| TB 2353 | White | 150°C | ✔️ | ✔️ | ||||

| Precote 5 | Light blue | 160°C | ✔️ | ✔️ | ✔️ | ✔️ | ✔️ | ✔️ |

| Precote 15 | White | 200°C | ✔️ | ✔️ | ✔️ | ✔️ | ✔️ | ✔️ | |

| Precote 200 | Dark blue | 100°C | ✔️ | ✔️ | ✔️ | ||||

Quality

Our sites are all ISO 9001 certified, and our quality systems meet the specific requirements of the automotive and aerospace industries.

Certifications

Our products are approved to numerous automotive standards:

- Renault CDC 39.02.010

- PSA B14.12.35

- Volvo STD 1262.2

- Ford WX 201