Thread-locking solutions developed by Soprima Industrie

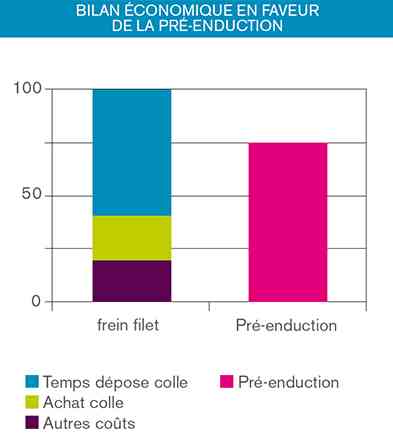

Pre-coating is a technique developed thirty years ago for car manufacturers. In the 80s, fasteners were secured using liquid adhesives, but their removal posed numerous problems on assembly lines. The pre-coating solution came to the fore, thanks to its ease of use and favorable economics.

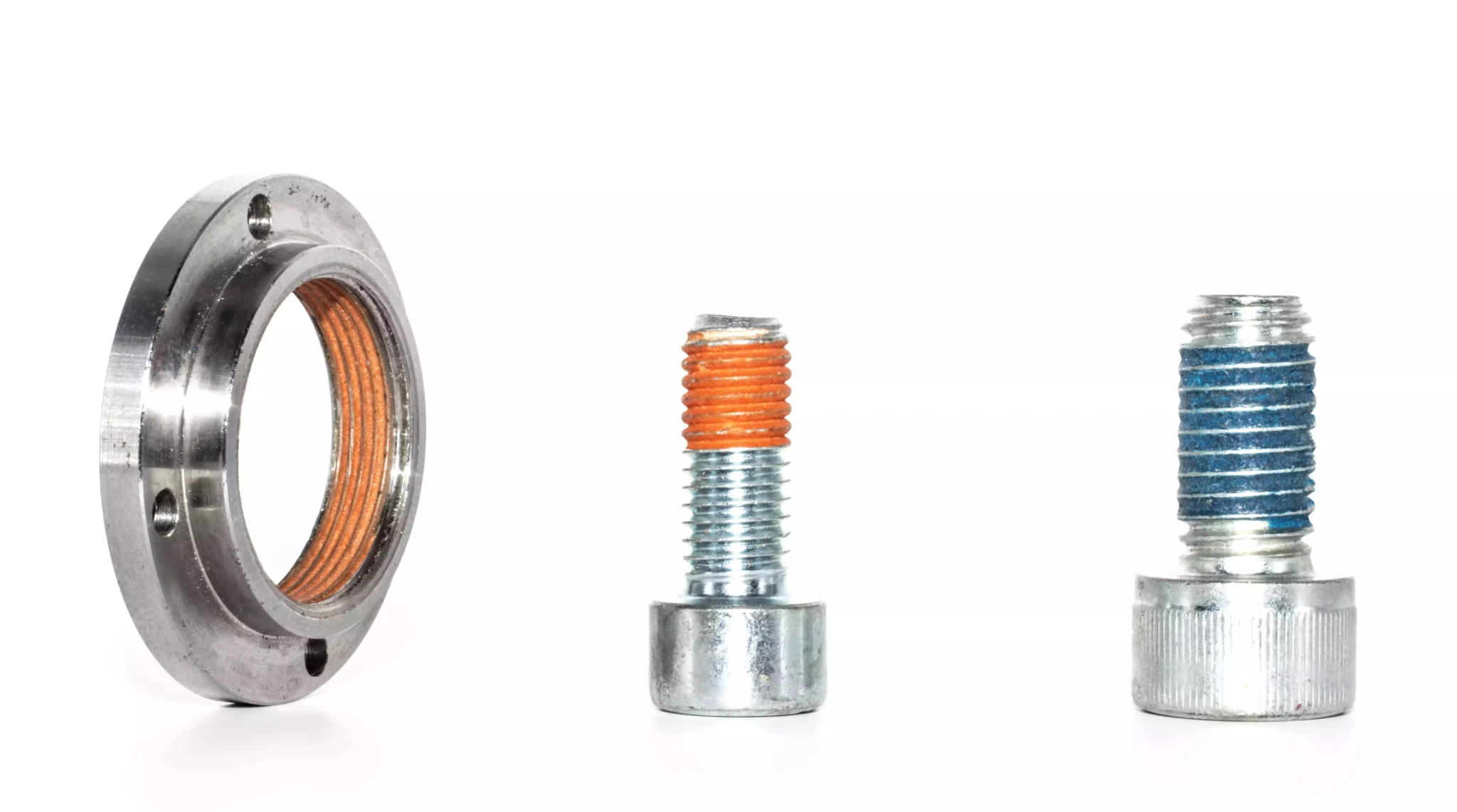

Pre-coating is now used in all industries. Our fleet of special machines enables us to produce small series (1000 parts) as well as very large series (1 million parts) on a very wide range of applications: screws from M1 to M20, nuts from M5 to M30, pins, studs, fittings, plugs, inserts, etc. special parts.

Locking by bonding function

Numerous thread-locking techniques exist, but the most widespread consists of applying a drop of threadlocker (anaerobic glue) to the thread or tapping of threaded bolting components: screws, nuts, studs, threaded rods, plugs, etc.

This threadlocker solution is effective in bonding the 2 parts of the assembly, but it is costly to implement and subject to variations in results. Liquid threadlocker has therefore been replaced in many applications by an adhesive pre-coated on the threads.

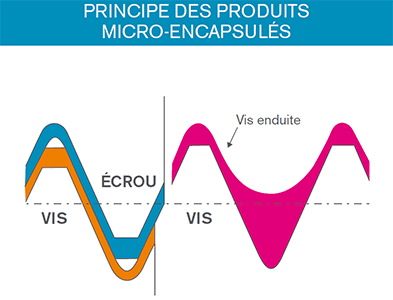

The technique consists in pre-coating the threaded fastener with a microencapsulated adhesive that activates only during assembly. During screwing, the adhesive released by the bursting of the microcapsules mixes with the hardener and bonds the threaded elements together like a conventional threadlocker.

The advantages of locking by bonding

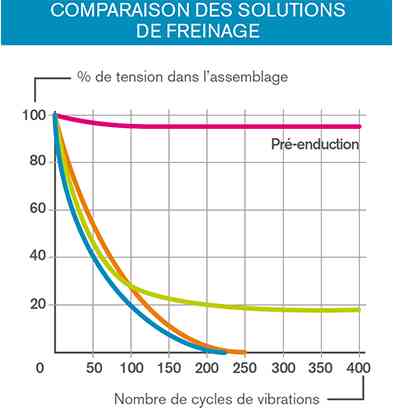

Pre-locked fasteners replace conventional locking solutions thanks to their incomparable technical and economic performance:

- Superior performance : unrivalled vibration resistance

- Easy design : replaces standard fasteners without redesigning the assembly

- Rapid assembly : no need for washers or glue

- Technical control : the amount of product applied to the assembly is always the same

- Uncompromising quality: no possibility of forgetting the locking process

- Significantly lower assembly costs : high productivity in the workshop or on site

- Elimination of health and safety problems associated with liquid glues

Features and products

The pre-coating products we use come from our long-standing partnerships with leading manufacturers.

| Suppliers | Product | Color | Functions | |

|

SO21B | Dark blue | High strenght | |

| SO22R | Orange | High strenght | ||

| 3M2510 | Orange | High strenght and sealing | ||

| 3M2353 | Dark blue | High strenght | ||

|

Precote 30 | Yellow | Average strenght | |

| Precote 80 | Pink | High strenght | ||

| Precote 85 | Turquoise | High strenght | ||

Reusable locking function or Nylon locking

Reusable locking is obtained by pre-coating the thread with a polyamide plastic. When screwed in, the plastic layer applied to the thread is compressed. The radial tension created by the elastic deformation of the product causes locking by increasing friction. The locking function can be repositioned, as the deformation of the polyamide is partially reversible, making it possible to screw and unscrew the part several times. The locking function is active immediately after screwing, but unscrewing torques are lower than those obtained by gluing.

To achieve the reusable locking function, we cold-apply a polyamide resin around the entire circumference of the thread. The locking torque can be adapted to the requirements of the application.

Polyamide deposition is particularly suitable for adjusting screws, which can be repositioned several times. This technique is also used for the temporary positioning of pre-assembled screws awaiting tightening. Reusable locking prevents the screw from being lost during conveying or transport, while enabling the final screwing operation.

This type of locking, also known as “Nylon Locking”, is also suitable for parts that need to be regularly dismantled for maintenance or equipment reconfiguration.

The advantages of reusable locking

Can be reused several times

Good resistance to shock and vibration

Adjustable torque depending on application

Adjustable patch position and width

Eliminates additional locking parts: self-locking nut, lock washer, pin, etc.

Locking with or without tension in the assembly

No polymerization: locking and sealing are immediate

Good resistance to chemicals (alcohols, petroleum, diesel, oils, kerosene, etc.)

Features and products

The pre-coating products we use are derived from our long-standing partnerships with leading manufacturers.

| Supplier | Products | Color | Functions |

| Precote 10-1 | Green | Low strength + reusable locking |

Quality

All our sites are ISO 9001 certified, and our quality systems meet the specific requirements of the automotive and aerospace industries.

Certifications

Our products are approved to numerous automotive standards :

- Renault CDC 39.02.010

- PSA B14.12.35

- Volvo STD 1262.2

- Ford WX 201